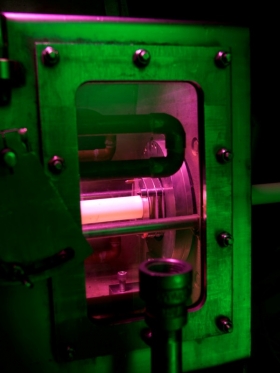

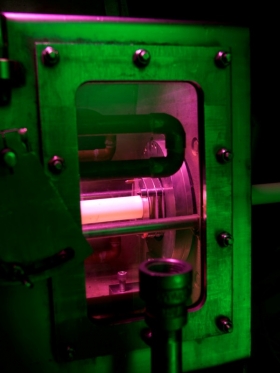

Teel is a world-class extruder of custom plastic tubing and profiles. We have been doing extrusion for over 70 years and are continuing to push the limits of possible in extrusion. We process over 50 different thermoplastic resins in an average year and work on everything from HDPE and PP to TPU and flex PVC to FEP and PEEK.

Teel is a world-class extruder of custom plastic tubing and profiles. We have been doing extrusion for over 70 years and are continuing to push the limits of possible in extrusion. We process over 50 different thermoplastic resins in an average year and work on everything from HDPE and PP to TPU and flex PVC to FEP and PEEK.

Teel’s flagship facility houses 27 extrusion lines from 1.0″ up to 3.5″. We manufacture parts from 0.025″ OD to 10″ OD. We routinely run two- and three-layer products with capability of going up to seven layers.

Teel services many markets with its extruded products. Teel’s products are shipped worldwide to customers that require highly engineered and tight-tolerance products for regulated applications. Teel’s current end-use markets include film cores, water treatment, flexible PVC, medical packaging, automotive, piping systems, medical device components, cosmetics, filtration, food dispensing, conduit, and industrial equipment, among others.

Click on specific markets in the right panel to learn more.

Teel provides top-quality cores to the film market. Teel’s plastic cores are used in numerous applications where their dimensional stability, smooth surface finish, and lack of particulate are critical to the success of the end application.

READ MORE

Teel Plastics is an experienced supplier of flexible PVC tubing for medical applications. We have manufactured PVC tubing for the medical market for over thirty years and have the cutting edge equipment needed to make tubing that is both high quality and economical.

READ MORE

Teel offers extruded industrial piping for the pressure pipe, oil and gas, and communications cable markets. Our industrial piping options include traditional and cutting edge materials that meet or exceed regulatory and performance standards.

READ MORE

Teel extrudes swab sticks in a variety of materials and numerous configurations. We can work with customers from design to production to produce swabs for the healthcare industry and beyond.

READ MORE

Teel specializes in the production of tubing and profiles for materials in demanding end use applications. We routinely process PEEK, PAEK, PVDF, PPS, polyamides, and other highly engineered materials intended for service conditions above 150° C.

READ MORE

Teel was a pioneer in developing coextrusion technology for many applications. Today, we frequently use coextrusion to help customers solve challenging problems with part functionality.

READ MORE

Teel is a world-class extruder of custom plastic tubing and profiles. We have been doing extrusion for over 70 years and are continuing to push the limits of possible in extrusion. We process over 50 different thermoplastic resins in an average year and work on everything from HDPE and PP to TPU and flex PVC to FEP and PEEK.

Teel is a world-class extruder of custom plastic tubing and profiles. We have been doing extrusion for over 70 years and are continuing to push the limits of possible in extrusion. We process over 50 different thermoplastic resins in an average year and work on everything from HDPE and PP to TPU and flex PVC to FEP and PEEK.

©2024 Teel Plastics

©2024 Teel Plastics