Taking Plastic Medical Device Concepts to Scaled Production

Teel is an ISO 13485-certified manufacturer of both extruded and injection molded products for the medical device market, and complexity is our specialty. From regulatory guidance to engineering and development, Teel can help you navigate the complexity of the medical market and get your medical device concept off the ground. Our advanced manufacturing facilities and technology can then take your prototype to scale, producing it with the tight-tolerances and reliable quality required of today’s medical devices.

A Collaborative Partner in the Medical Device Market

Our collaborative approach is highly responsive and fluid. We’re known for going beyond the basics and providing deeper guidance and partnership with our engineering resources, plastics expertise, and award-winning customer service. Each of our capabilities serves as a resource to draw from as we work together to bring your device to market.

Engineering and Development

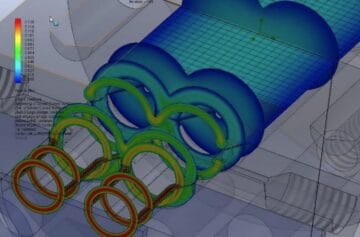

Teel has an experienced team of engineers and technical experts offering full-service design-for-manufacturability (DFM), co-engineering, rapid prototyping, and regulatory support, and we offer analytical testing via our in-house ISO 17025-accredited analytical lab specializing in polymer science. We use advanced flow modeling technology for optimizing the extrusion process and a Scientific Molding approach to injection molding design.

Broad Material Selection

We have experience working with an extensive catalog of medical-grade polymers, including high-temperature, water-sensitive, and custom-blended materials. Available options include flex PVC, PEBAX, flex PVC and silicone alternatives, sustainable options, and more. We also offer development of custom materials not commercially available.

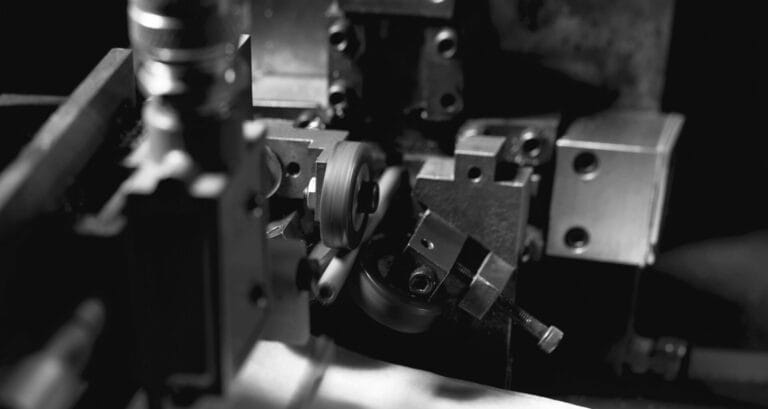

Extrusion

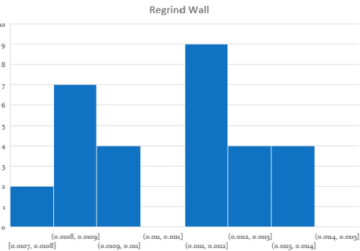

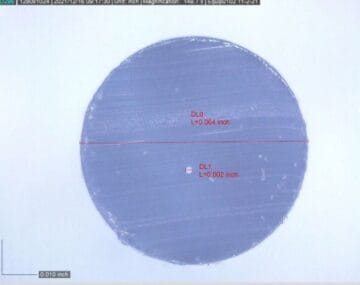

Teel is a leader in tubing extrusion with capabilities ranging from tight-tolerance thin-wall, multilumen, paratube, multilayer, and mandrel extrusion options. Our medical manufacturing facility houses 30+ extrusion lines offering tight dimensional control with in-line measurement and SPC tools. Our use of flow modeling technology helps ensure production efficiency and precise control of variables.

Injection Molding

We offer high-cavitation molds for scalable production, overmolding capabilities for complex assemblies, and robotics-assisted operations for faster production times. Our use of conformal cooling mold design for parts with thin and delicate structures helps ensure consistent part integrity. Our facility houses 17 Arburg machines in a variety of sizes.

Clean Rooms

We house two ISO Class 8 clean rooms for sensitive medical devices and offer clean room capacity for extrusion, injection molding, finishing, and packaging.

Sustainability

We offer bio-based resins and plasticizers (phtalate free) as sustainable options. Packaging and process options for reducing cost and environmental impact are also available. Teel’s medical facility was designed with sustainability in mind and includes multiple energy efficient and environmental-impact reducing features.