Back

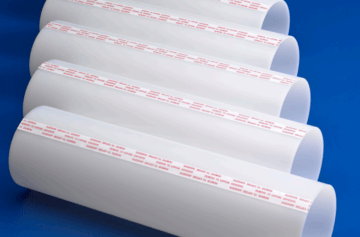

Teel has been producing tight-tolerance plastic cores for specialty film manufacturing and clean room processing for over 50 years.

Whether you require clean room quality cores, part to part consistency, or core identification in the field, Teel can help determine the right core for your needs. We can manage your inventory through kanban programs, web portals, or consignment programs, and our injection molding capabilities allow us to maximize freight and reduce costs by bundling injection molded end plugs with extruded plastic cores.

Tolerances:

•

ID: +/-0.015˝

•

OD: +/-0.0075˝

•

Wall: +/-0.005˝

•

Length: +/-0.063˝

•

Bow: +/-0.015˝/ft

•

Roundness: 0.030˝ max

Materials:

•

ABS

•

HIPS

•

PP

•

PE

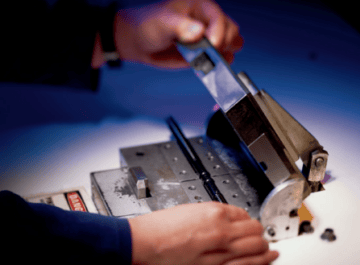

Custom Offerings:

•

Taping

•

Bagging

•

Punching

•

Chamfering

Size Range:

•

ID – 1˝ to 8˝

•

Wall – 0.050˝ to 0.485˝

View our Flex Film Core Capabilities

We are always looking for talented individuals to join our team.

View Careers